Pitbull® Clamps

Measurements Available: Inch, Metric

Pitbull® Clamps

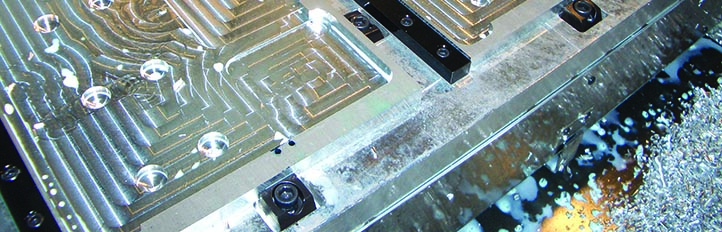

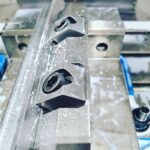

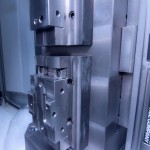

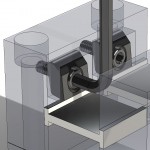

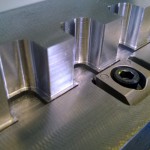

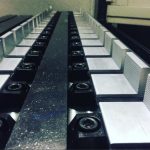

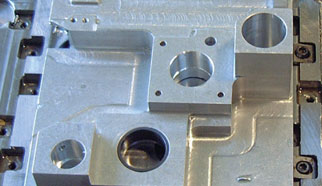

The revolutionary Pitbull® Clamp remains the lowest profile, highest holding force clamp in the industry today. High vertical and horizontal clamping forces are generated, considering the size of the Pitbull® Clamps.

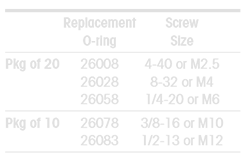

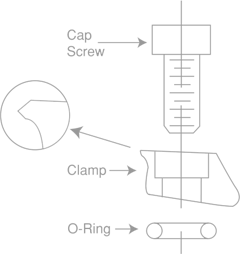

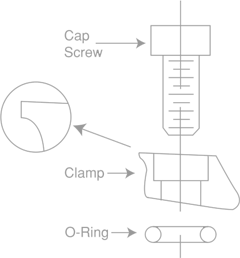

It uses a standard cap screw and an oil resistant O-ring. The Pitbull® Clamp is available in 5 sizes and several styles, a tool steel knife edge for aggressive stock removal, a tool steel blunt edge for general purpose, a brass version to help prevent marring the workpiece and a machinable version.

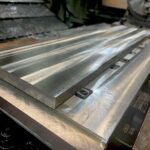

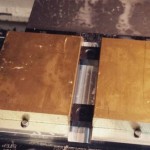

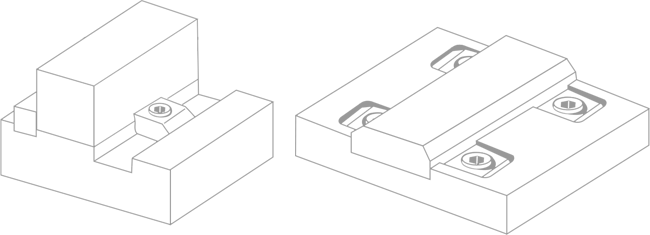

Also available is the Pitbull® Wear Plate. This shim provides a hard barrier between Pitbull® Clamp and fixture, preventing distortion of back wall when using aluminum or mild steel fixtures. Simple solution to keep fixtures light, maintain full clamp travel and holding forces at max pressure. Refurbish old fixtures or add to existing aluminum fixtures to maximize machining capabilities.

Unique Features of Pitbull® Clamps |

||

|

|

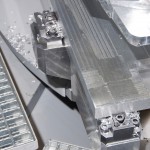

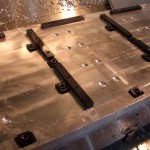

Courtesy of Straitline Components Courtesy of Straitline Components |

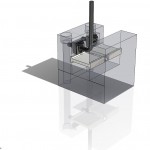

Creating Fixtures is Easy. . . Simply: |

|

PATENT NO. 6435496 |

|

Inch

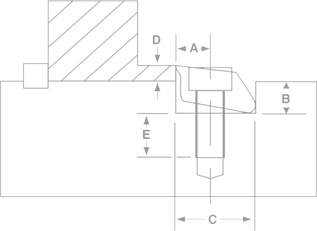

| Part No. | Description | A | B | Clamp Width C |

D* | E | SHCS Screw Size |

Max Torque (ft/lbs) |

Holding Force (lbs.) |

Total Throw |

No. Clamps Per Package |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 26000 | CAD | Tool Steel, Knife Edge | .150 | .140 | .375 | .075 | .260 | 4-40 | 1.30 | 650 | .0075 | 8 |

| 26010 | CAD | Tool Steel, Blunt Edge | .150 | .140 | .375 | .075 | .260 | 4-40 | 1.30 | 650 | .0075 | 8 |

| 26015 | CAD | Brass, Blunt Edge | .150 | .140 | .375 | .075 | .220 | 4-40 | .41 | 200 | .0075 | 8 |

| 26020 | CAD | Tool Steel, Knife Edge | .200 | .187 | .500 | .100 | .390 | 8-32 | 3.70 | 1500 | .016 | 8 |

| 26030 | CAD | Tool Steel, Blunt Edge | .200 | .187 | .500 | .100 | .390 | 8-32 | 3.70 | 1500 | .016 | 8 |

| 26040 | CAD | Brass, Blunt Edge | .200 | .187 | .500 | .100 | .340 | 8-32 | 2.00 | 400 | .016 | 8 |

| 26050 | CAD | Tool Steel, Knife Edge | .300 | .280 | .750 | .150 | .570 | 1/4-20 | 14.50 | 3600 | .024 | 6 |

| 26060 | CAD | Tool Steel, Blunt Edge | .300 | .280 | .750 | .150 | .570 | 1/4-20 | 14.50 | 3600 | .024 | 6 |

| 26065 | CAD | Brass, Blunt Edge | .300 | .280 | .750 | .150 | .440 | 1/4-20 | 4.10 | 950 | .024 | 6 |

| 26070 | CAD | Tool Steel, Knife Edge | .400 | .450 | 1.00 | .250 | .710 | 3/8-16 | 30.00 | 6000 | .050 | 4 |

| 26075 | CAD | Tool Steel, Blunt Edge | .400 | .450 | 1.00 | .250 | .710 | 3/8-16 | 30.00 | 6000 | .050 | 4 |

| 26080 | CAD | Tool Steel, Knife Edge | .600 | .640 | 1.50 | .375 | .770 | 1/2-13 | 108.30 | 12000 | .075 | 2 |

| 26085 | CAD | Tool Steel, Blunt Edge | .600 | .640 | 1.50 | .375 | .770 | 1/2-13 | 108.30 | 12000 | .075 | 2 |

Metric

| Part No. | Description | A | B | Clamp Width C |

D* | E | SHCS Screw Size |

Max Torque (N.m.) |

Holding Force (N.) |

Total Throw |

No. Clamps Per Package |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 56000 | CAD | Tool Steel, Knife Edge | 3.81 | 3.55 | 9.52 | 1.90 | 6.60 | M2.5 | 1.8 | 2800 | .190 | 8 |

| 56010 | CAD | Tool Steel, Blunt Edge | 3.81 | 3.55 | 9.52 | 1.90 | 6.60 | M2.5 | 1.8 | 2800 | .190 | 8 |

| 56015 | CAD | Brass, Blunt Edge | 3.81 | 3.55 | 9.52 | 1.90 | 5.59 | M2.5 | .56 | 875 | .190 | 8 |

| 56020 | CAD | Tool Steel, Knife Edge | 5.08 | 4.75 | 12.70 | 2.54 | 9.90 | M4 | 5.6 | 6600 | .406 | 8 |

| 56030 | CAD | Tool Steel, Blunt Edge | 5.08 | 4.75 | 12.70 | 2.54 | 9.90 | M4 | 5.6 | 6600 | .406 | 8 |

| 56040 | CAD | Brass, Blunt Edge | 5.08 | 4.75 | 12.70 | 2.54 | 8.64 | M4 | 2.8 | 1750 | .406 | 8 |

| 56050 | CAD | Tool Steel, Knife Edge | 7.62 | 7.11 | 19.05 | 3.81 | 14.48 | M6 | 22.5 | 16000 | .610 | 6 |

| 56060 | CAD | Tool Steel, Blunt Edge | 7.62 | 7.11 | 19.05 | 3.81 | 14.48 | M6 | 22.5 | 16000 | .610 | 6 |

| 56065 | CAD | Brass, Blunt Edge | 7.62 | 7.11 | 19.05 | 3.81 | 11.18 | M6 | 5.6 | 4200 | .610 | 6 |

| 56070 | CAD | Tool Steel, Knife Edge | 10.16 | 11.43 | 25.4 | 6.35 | 18.03 | M10 | 40.6 | 26000 | 1.270 | 4 |

| 56075 | CAD | Tool Steel, Blunt Edge | 10.16 | 11.43 | 25.4 | 6.35 | 18.03 | M10 | 40.6 | 26000 | 1.270 | 4 |

| 56080 | CAD | Tool Steel, Knife Edge | 15.24 | 16.26 | 38.1 | 9.52 | 19.56 | M12 | 145.0 | 50000 | 1.900 | 2 |

| 56085 | CAD | Tool Steel, Blunt Edge | 15.24 | 16.26 | 38.1 | 9.52 | 19.56 | M12 | 145.0 | 50000 | 1.900 | 2 |

|

|

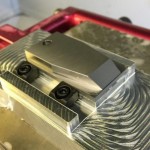

Both versions of the tool steel clamps generate the same clamping pressure. However, the knife edge clamps bite into the material for more aggressive machining, while the blunt edge is less likely to mark the workpiece. |

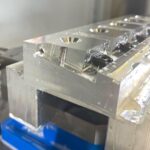

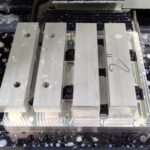

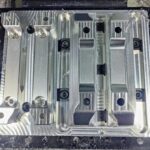

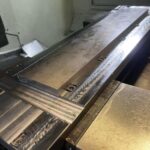

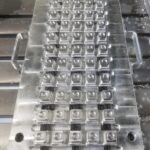

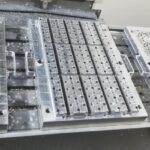

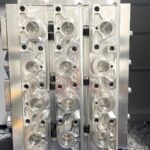

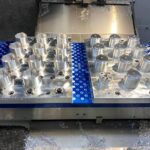

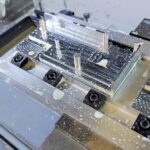

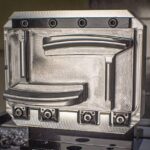

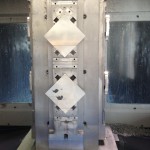

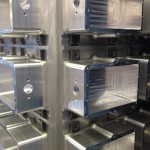

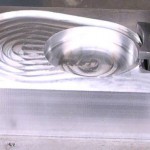

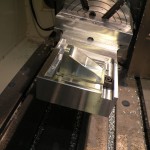

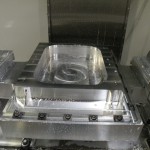

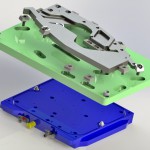

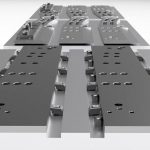

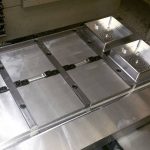

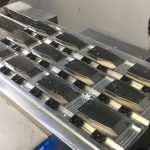

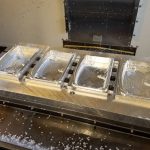

Fixture Examples |

|

|

Using a steel rail behind clamp in aluminum fixtures when applying maximum torque prevents displacing metal at pivot point. |

Applications

- Image courtesy of Pete Denness

- Image courtesy of Justin Lowe

- Image courtesy of Justin Lowe

- Image courtesy of Charles Ebenezer Eastman Sanborn IV

- Image courtesy of @grayopscnc

- Image courtesy of m95machining

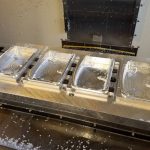

- Ken Robertson -MiteeBite Products Facebook Community – I used them on a pallet recently. Wanted something narrower so I’d have more meat for the pitbull clamps. Worked excellent here.

- @hanes_spanntechnik

- @hanse_spanntechnik

- @gibblespeed_ – I’m digging the #miteebite setup.

- @gibblespeed_ – I’m digging the #miteebite setup.

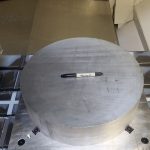

- @spartanmachinellc – Wow I love these @miteebite #pitbullclamps we had to face down even longer plates this week. So I expanded my original fixture design, and got a @iscarcuttingtools HELIALU cutter and shredded the material. Perfect flatness and a gorgeous finish!

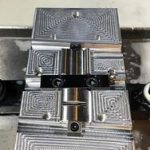

- Peter Stokes – Mitee-Bite Facebook Community – My latest mitee bite fixture. All three have removable top plates located with 4 Mitee Bite ID clamps while operator reloads another set of identical top plates while machine continues to run. 60 complete parts in 2.5 hrs(can speed up the program a bit) with 4 total operations on each part. Fun to design and make.

- Peter Stokes – Mitee-Bite Facebook Community – My latest mitee bite fixture. All three have removable top plates located with 4 Mitee Bite ID clamps while operator reloads another set of identical top plates while machine continues to run. 60 complete parts in 2.5 hrs(can speed up the program a bit) with 4 total operations on each part. Fun to design and make.

- Image courtesy of @jack_vanderpols.

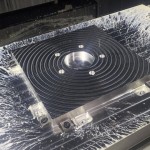

- Image courtesy of @sultans_of_steel. “I finally got around to making a PitBull fixture by @miteebite it worked perfectly! I had been trying to face down these alum plates to within .001 thickness, but it Was proving impossible just holding it with vises. So It became the perfect opportunity to try these out! I am only bummed I haven’t used them sooner! “

- Image courtesy of @sultans_of_steel. “I finally got around to making a PitBull fixture by @miteebite it worked perfectly! I had been trying to face down these alum plates to within .001 thickness, but it Was proving impossible just holding it with vises. So It became the perfect opportunity to try these out! I am only bummed I haven’t used them sooner!”

- Image courtesy of @tecuscncteknolojileri

- Image courtesy of @tecuscncteknolojileri

- OP1 – Photo credit @jprecisionmachine

- Image courtesy of @advancedmachineengineering

- Image courtesy of @superstarcomponents

- Image courtesy of Addison Bosley

- Image courtesy of @ioscnc

- Images courtesy of @jason_chipley

- Image courtesy of Paul Poindexter

- Image courtesy of @hanse_spanntechnik

- Image courtesy of @grayopscnc

- Image courtesy of @zandercncsolutions

- Image courtesy of @zandercncsolutions

- Image courtesy of @aaronottosen

- Image courtesy of @factorydaily

- Images courtesy of @machiningllc

- Image courtesy of @rogue_machine

- Image courtesy of @gmc_cnc_machining

- Image courtesy of @liberationautomation

- Image courtesy of @mtnmachinist

- Image courtesy of @mtnmachinist

- Image courtesy of @cape_town_cnc

- Image courtesy of Olson Manufacturing